Gravimetric Auto Dosing & Mixing System (ADMG)

Categories : Dosing and Measuring Equipment

COST SAVE: ADMG can measure powder resin, granule resin, master-batch, or additive precisely. EASY OPERATE: By entering the percentage of each batch and supply value to operate effectively, HMI automatically calculates all required values operate and monitor by single personnel or connect a PC through a modern to through a modern to maintain the system or solve problem. HMI is dynamic and versatile to provide the most efficient and economic operation. ACCURACY & CONSISTENCY: ADMG automatically measures the required amount accumulatively in order when you add extra resins or additives which will not affect the precision of dosing or mixing. ERROR REPORT: Error problems are recorded the time by day, month, and year for the maintenance. EASY CLEAN & SPACE SAVE: Stainless design and individual function units are easy to discharge and install.

Gravimetric Blenders - SGB

Categories : Dosing and Measuring Equipment

• Evenly mixing of materials after accurately weighing, control accuracy strictly of ±0.1~±0.3%. • Auto calibration after each material weighting ensures accuracy. • Up to 100 recipes can be stored for later use. • Alarm log function. • All parts detachable for easy cleaning. • For SGB-600 and models below, machine mount model is the standard supply (equipped with magnetic base,manual discharge valve), optional pneumatic slide gate is available also. • For SGB-2000 and models above, floor stand is the standard supply (equipped with moveable floor stand, storage hopper and pneumatic slide gate), optional SBU suction box is available also. • Has the function of recycled material compensation (recycling hopper is standardly equipped with low level switch). Aberration coompensation can be automatically calculated based to the feeding amount of recycled materials. • Memory card can be optional selected to store ratio information for product quality control. • Hopper low level sensor can be optional selected to send alarm when material is insufficent. • Optional analog signals (0~10V) output function for screw automatic adjusting of extrusion molding machine. • RS485 communication is optional to realize the centralized monitoring of connecting with molding machine. • Floor stand, pneumatic slide gate, storage bin and suction box should be optionally purchased for floor mounting. (Applicable for SGB-600 and models below)

Gravimetric Master-Batch Feeder (MF-G)

Categories : Feeders

The latest gravimetric master-batch feeder with lose-in-weight design (MF-G) increases your accuracy caused by the uneven size of master-batch or recycled resins. Customization is available to combine multi units and more. Easy discharged design makes change color faster with no more sampling for setting. ‧ Roller type of screw pipe is special designed which makes cleaning, discharging material and maintenance work easier. ‧ With the integrated adapter of mixing and stirring function, no more worry for the feeder to be stuck. ‧ Production record will check the using weight of material during the process. ‧ It can equip with injection-type cycle operation, and a time-delayed control design. It can prevent the unstable additional rate of the master-batch from the different times of mold. ‧ Error data is recorded by day, month, and year for adjustment and maintenance. ‧ Be able to save 40 groups molding data, customized formulations, recipes…Recall the records quickly, eliminating the need for manual records and re-enter the program, but also reduce manual errors. It’s easy to operate. ‧ The Human Machine Interface (HMI) can connect to Ethernet and RS485. With Industry 4.0 features, the feeder can integrate with existing auxiliary equipment.

Gravimetric Doser SGD

Categories : Dosing and Measuring Equipment

SGD gravimetric doser is suitable for continues precision dosing of masterbatch to the plastic process machine. The unit has a selection of four dosing screw sizes for different throughput needs. The unit can supports up to two sets of dosing screws for various material receipt. The lose-it-weight technology allows doser to measure and correct dosing to realize constant dosing precision. SGD syncronize dosing speed in extruder mode via analog 0~10V input from the extruder. Combination of Shini VL venturi loader realizes auto conveying of material to SGD at all time.

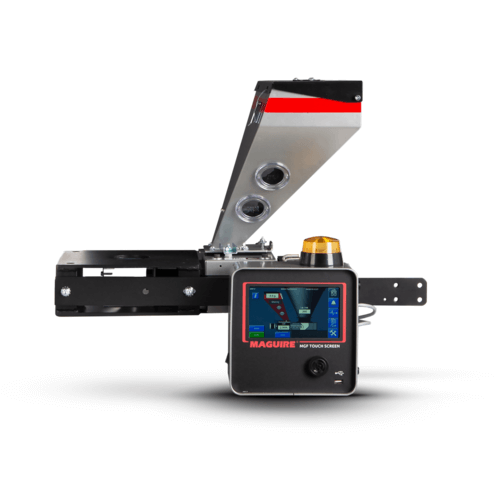

MGF Gravimetric Feeders

Categories : Dosing and Measuring Equipment

Robust hardware, integrated with industry-leading software control to achieve repeatable consistent dosing accuracy. Unique twin load cell technology Dosing accuracy ± 0.2% on 1% setting Feeder ideal for all molding and extrusion processes